Shop Categories

Your Reviews

Read More

Trade Account Login

REGISTRATION

I'm Baaaaaackkkkkkk!!!!

I'm Baaaaaackkkkkkk!!!!

Due to an eye injury, my metalsmthing journey came to an abrupt end in March!!!

Due to an eye injury, my metalsmthing journey came to an abrupt end in March!!!

One of the most frustrating things during the Coronavirus lockdown, was not being able to spend the time in my little jewellery studio in the attic.

Due to an eye injury, it meant taht my vision on one of my eyes was impaired due to the number of floater formed when my eye contracted slighted, so much so it was like looking through tissue paper.

I have been itching to try and create some new pieces, but as most of my designs required some soldering, that really did put paid to that idea.

Anyway, with a few days break, I decided that it was time to get back into the making groove.

I brought a rolling mill just before Christmas, to add some textures to the metal, and so far have not put it through it's paces, so I thought now would be a good time to see what it can do.

I have seen some rolling mill plates on-line, which wasn't quite what I was after, and at £40 a pop, I think are quite expensive.

It was with this in mind that I though I would have a go at creating a texture template myself.

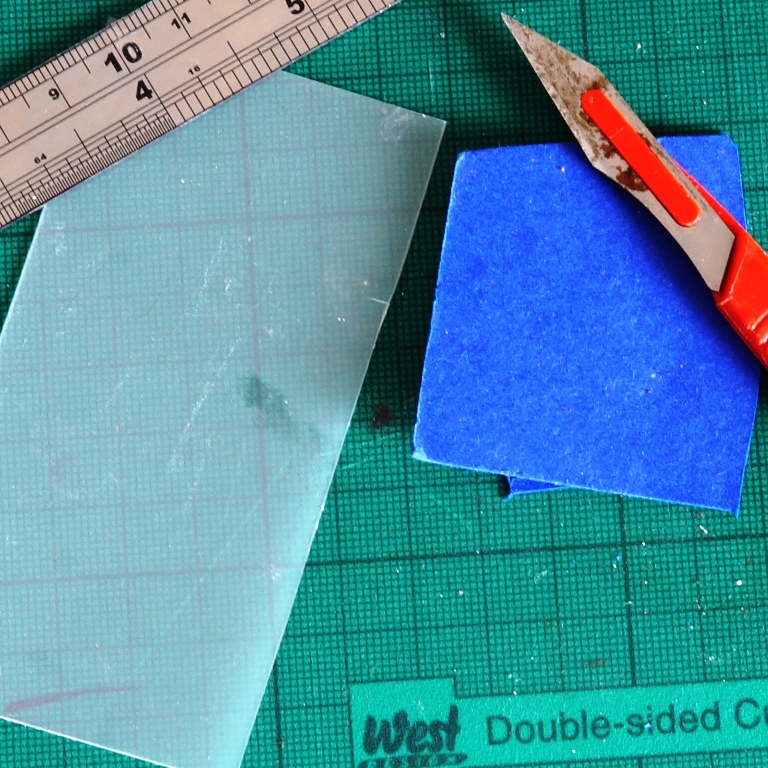

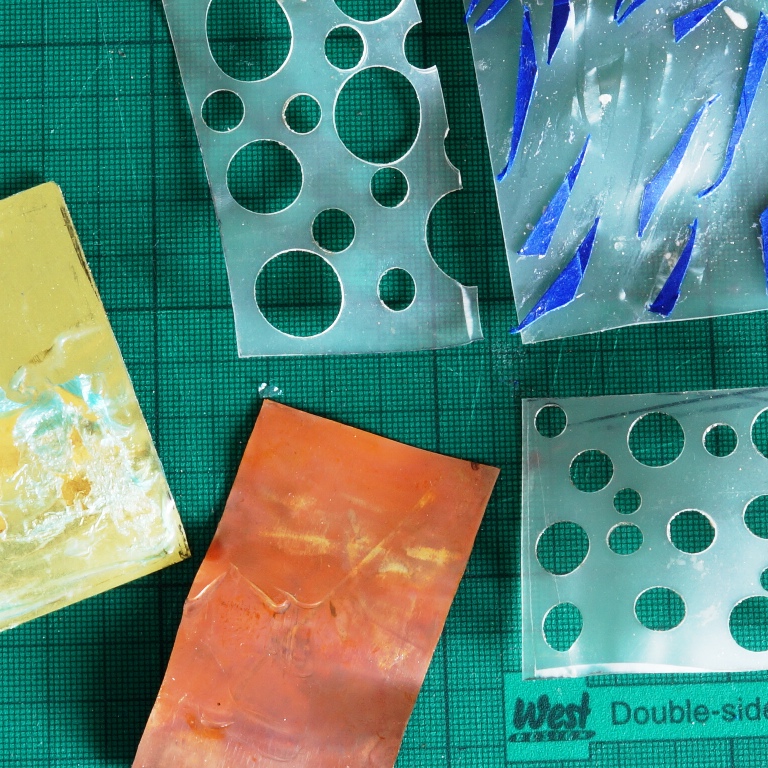

I have a plastic sheet and card to start with, and granted it looks like a bit of a craft project:

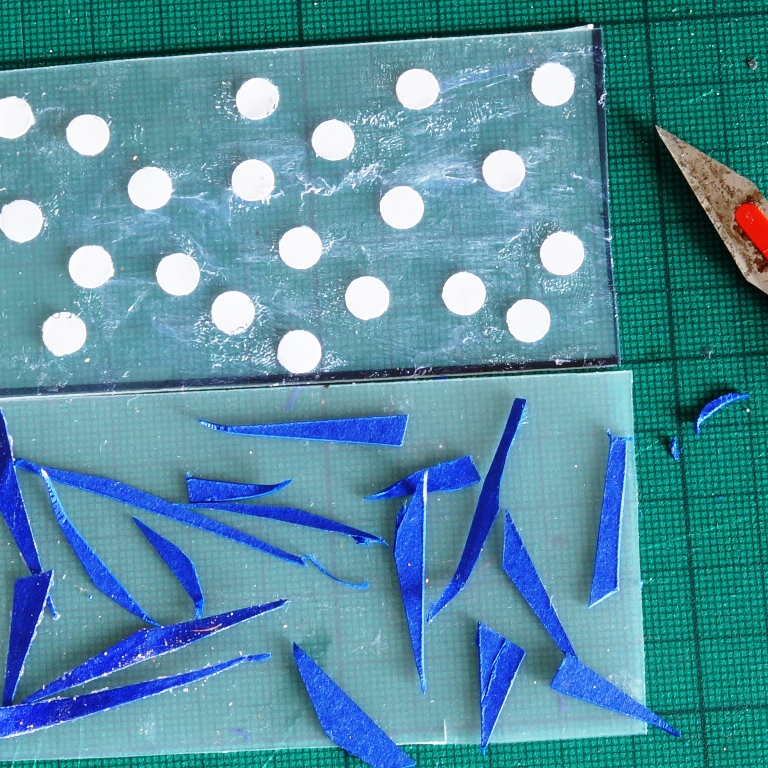

My first idea is to create a spotted texture effect, so I use the reminants of my hole punch and glue them on to the plastic template sheet.

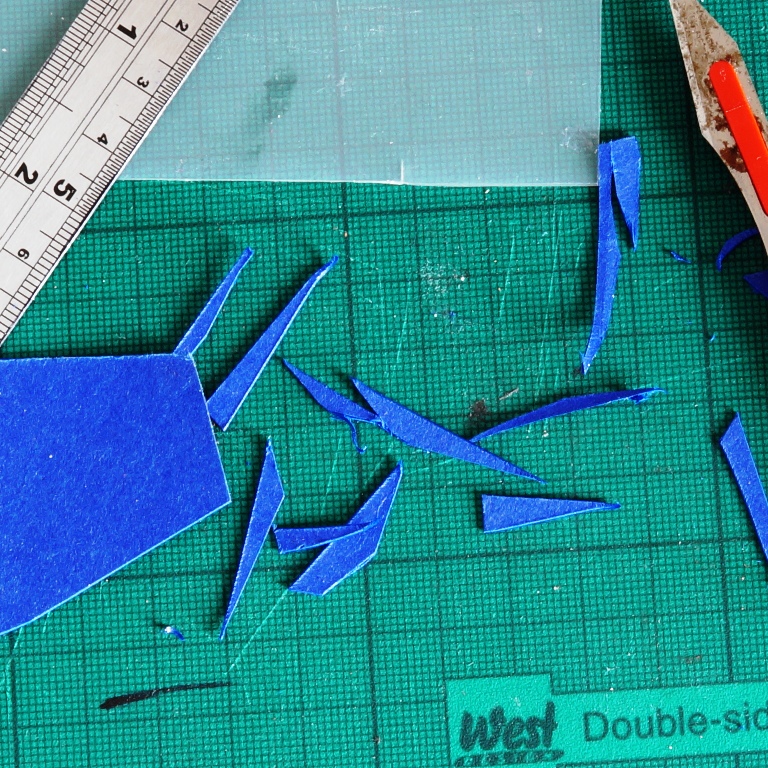

My second idea is to cut random triangle shapes of different sizes, shape and degrees, and randomly glue them to plastic template sheet:

The final glued up templates:

Now for the moment of truth!

I add a piece of copper and the random triangle template and roll it through the rolling mill.

The results are not fantastic, and I also realise that I've left the plasic covering on and the roller has distroyed the plastic tempate with some of the card coming away from the plastic!

Back to the drawing board

I then take this idea further and decide on another rectangle sheet to cut out random triangle shapes, sizes and degrees, but soon abandon that I idea as the triangles are not coming out as cleanly as I want.

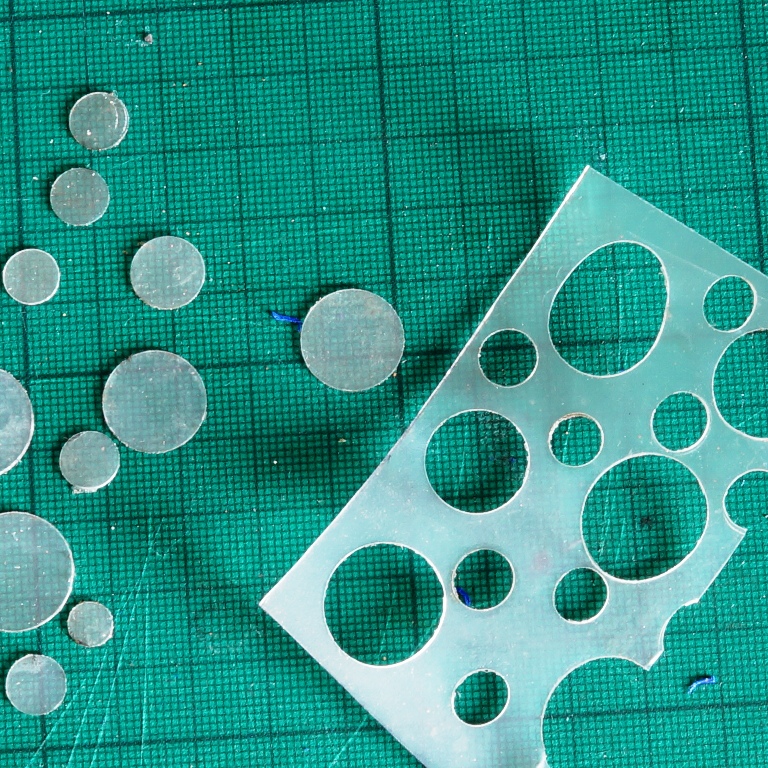

Then I have a euruka moment, and use my disc cutter to create two random circle template with different sized circles:

I have to say I'm pretty pleased with myself and the result of these last two templates.

I cut out a pieace of brass to protect the rollers, make sure I remove the plastic covering the copper, and anneal it before passing it through the rolling mill with the circle cutout template:

Strangly enough the template imprinted more on the brass than it did on the copper, whihc was the metal I intended it for:

Again it's back to the drawing board.

As a last ditch attempt to try and add texture to my copper sheet, I decide to use some 0.8 mm copper wire shaped into random wriggly shapes.

I sandwich the wire between some annealed copper and brass sheets, and try to roll it through the rolling mill.

This time the rolliing mill really struggled, and it was not bringing everything through straight, strangley enough it flatten the wire, but did not leave an impression on the copper!

So completed defeated the purpose of what I was trying to achieve, and it's at this point I decide to look at another methodof adding some interest and texture to my designs

I may have to look at re-calibrating the rolling mill, as it struggled to pass the metal through in a straight line.

But that's for another time...

Joolz xxx

0 Comments