Shop Categories

Your Reviews

Read More

Trade Account Login

REGISTRATION

Daddy didn't raise a quitter....

Daddy didn't raise a quitter....

For the last 3 months I have been working on a hoop design, that in reality is a simple design, but in reality is has been anything but

For the last 3 months I have been working on a hoop design, that in reality is a simple design, but in reality is has been anything but

3 months ago I had the idea to create a simple hoop earring.

As with all my all my designs I always start with copper, work out the design concept and making processkinks and gremlins, before moving onto sterling silver.

Starting with the classic circle shape, I wanted to create a pair of classic hoops ideal for everyday wear for work.

I thought that a hoop with a 15mm diameter would be ideal size.

I worked out the correct length of 7mm width copper I would need, taking into consideration the thickness of the metal, measured and sawed the right dimensions, without cutting myself, thats a win for me!

A bit of annealing and then shaping the metal was a dream.

So far so good....

The next step was to create a ear posts, as I know most people are a little uncomfortable having copper going through their ears, I thought some square sterling ilver wire would be a good way to allieve their concerns and give a contemporary feel to the hoop.

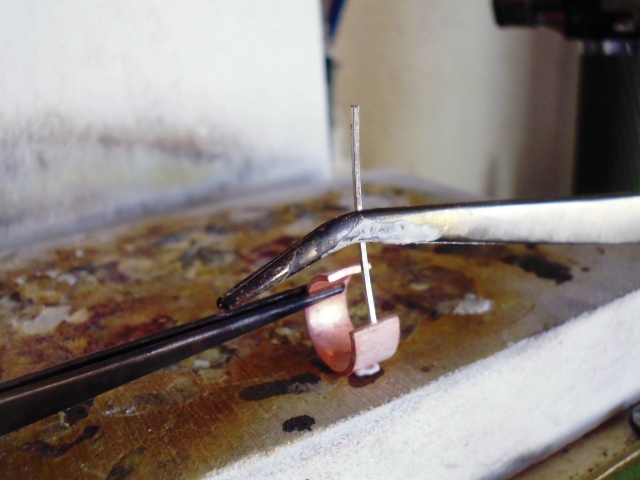

Ear posts all created and I am now ready to create the hoop. In essence this is a simple process of soldering the sterling silver ear post to the copper hoop. I have filed post surfaces flat so that there is no space, both edges are clean and have been fluxed to an inch of their existance.

And herein is were my hoop earring making plans grinds to an abrupt halt.

For the life of me I cannot solder these 2 metals together satisfactorily.

Try as I might it's just not happening!!!

For the next 3 months I try different soldering and making methods to create this hoop, but to no avail, and naturally my confidence in metal smithing jewellery making plummets, so much that I am no longer motivated to make anything, as soldering is the basis of all metal smithing especially bezel setting.

Although the making side of thing has ground to a halt, it does not stop me thinking of design ideas, or how I go about achieving the designs.

As luck would have it, I was scrolling through my instagram feed, and I come across a jeweller creating a hoop earring and shows the soldering set up. Naturally my interest is piqued, and I pay close attention to the tweezer placement technique. I then go onto Youtube and have a look at a few other examples, before heading upto my jewellery studio to put this into practice:

With baited breath and my little blowtorch in my hand I start the soldering process one more time....

Success finally!!!! the 2 pieces are securely soldered together and just to ensure that this was not a fluke, I managed to solder the other hoop earring to make a pair:

As you can imagine I am doing a happy dance in my little attic studio, with the music blaring of course, I have finally nailed it!!!

You can see from all my previous attempts of soldering there is quite is a lot of solder on the copper hoops, so starts the long ardous task of filing this down to clean up the earrings, once they have been pickled to get rid of the oxidation and excess flux.

The final thing is to polish:

Now as you know practice makes perfect, and it was in that vein that I decided to create 2 more copper hoops in a bigger and smaller size, and I have to say I was able to solder the posts on with no problems:

I love how these hoops came out, I think they are both classic and contemporary, Copper is such a gorgeous colour and really bring jewellery to life, so what do you think?

I would really love to hear your thoughts, so post something in the comments below.

Until next time

Joolz xxx

0 Comments